Each production company develops its own methods and practices for managing its activities. Some of them use extensive IT solutions, others are based on simple measurement tools. However, facing the challenges of the modern economy, every company must be aware that the development of an operating strategy, implementation of modern management systems and appropriate communication with recipients is now a necessity. And not only an opportunity that builds a competitive advantage. What to do when problems arise in the production company? Let's check.

Modern IT systems allow not only to effectively manage production and warehouse management. They are also able to control human resources, monitor the product life cycle and communicate with the internal and external environment. They allow you to automate and improve many tasks, increase work efficiency and make the right strategic decisions. Thanks to the implementation of integrated systems, the company's competitiveness increases, and the constantly changing needs and preferences of customers cease to be any problem.

How well do you communicate about your competitive advantages?

Bet on measurable benefits.

Problems in the production company resulting from the management of the production process

One of the most serious problems of production companies operating today is the lack of an appropriate plan that would allow them to effectively manage the production process. Inadequate description of production technology - recipes and routes - leads to inaccurate estimation of material needs, involvement of machines and human resources, as well as inadequate reporting of all activities performed.

Developing an action strategy should not be based on made-up assumptions and idealistic imagesin fact. An effective action plan must take into account the actual data, the current value of supply, the currently used production technology and the real capabilities of the company. Thanks to the precise planning of activities, we do not allow any gatheringToo much stock is too much frozen capital, which can lose its value significantly over time.

Modern manufacturing companies must strive to automate the planning of their activities, as well as the implementation of solutions. Thanks to this, most of the production processes will be carried out fully automatically. Meanwhile, many Polish companies still rely on simple spreadsheets. They do not realize that one poorly planned and completed order can negatively affect the entire production process. It can have long-term consequences for the entire company. The IT system, operating on the basis of historical data as well as minimum and maximum states, is able to present appropriate simulations in advance. Such forecasts help estimate the demand for specific resources and avoid errors in planning the production process.

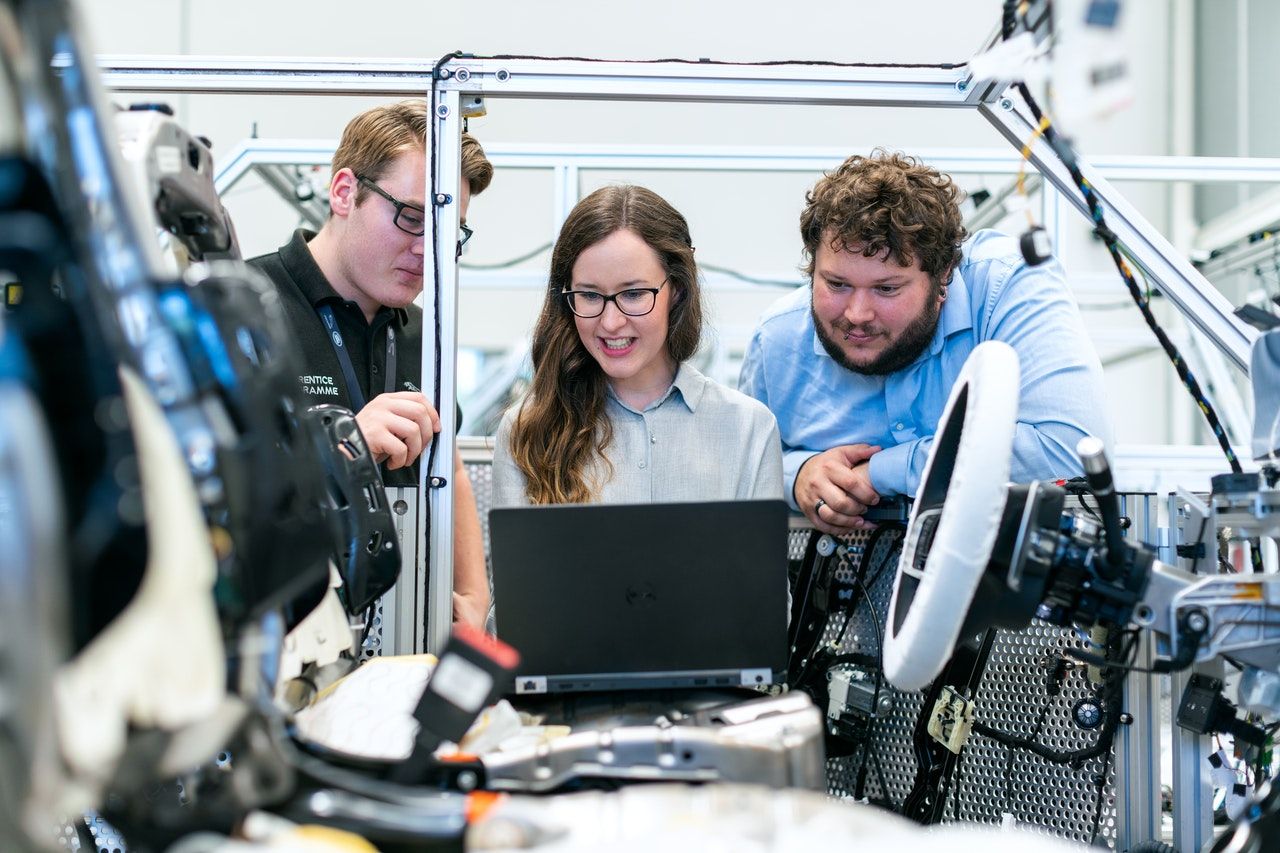

Problems of production companies related to human resource management

For several good years, many manufacturing companies have been complaining about the lack of qualified employees. On the one hand, this is related to the declining number of people studying in vocational schools as well as technical and engineering faculties. It is also important that work in production is perceived as less attractive than work in the service sector. The recipe for this may be to invest in educating your own staff of employees already at the stage of education in secondary schools. How can this be achieved? By offering an attractive system of apprenticeships and internships, cooperation with teaching staff or scholarships for the best students.

As important as what it acquiresnot new employees, it is to provide adequate care for those we already provide employment. If we want to keep the most valuable employees with us, we must not only provide them with adequate remuneration and additional social benefitse, but also take care of their development, appropriate training, comfort of work and appropriate operating procedures.

It is also important to skillfully conduct communication, receive feedback and implement the best ideas to improve the work of the entire team. This is what it serves, among others. worked out organizational culture of the company. It is also skillful team conflict resolution.

Manufacturing companies also have a problem with defining and communicating their competitive advantages. Fortunately, more and more companies are beginning to understand how important it is creating a brand image. Not only as a professional manufacturer, but also as a remarkable employer. They know that the lack of a marketing strategy can lead to a delayed response to changes in the market and changes in the behavior of potential customers.

Challenges standing on the way to solving problems of production companies

Manufacturing companies operating today have to face a whole host of challenges resulting from dynamically occurring market processes. One of them is the progressing globalization, as a result of which the market is flooded with cheaper counterparts from Asian countries. A chance to use this trend to your advantage is the specialization of production and looking for niches in newly emerging markets and focusing on niche marketing.

Another issue is the growing importance of ecology, which makes it necessary to consider the impact of our production on the state of the environment. The opportunity to use this phenomenon is to look for solutions based on the processing of elements that have already been used or manufactured, as well as the production of goods with lower energy consumption. In this case eco-marketing has tangible benefits.

The progressive increase in the importance of online sales, caused by change behaviors consumers who much more often use modern technologies and smartphones in the purchase process. Digitization and automation of production allows, among others transfer design work to the digital world, so that even before youWith the completion of a new product, we are able to check whether it will meet customer requirements. Intelligent factories and systems for self-management of production as well as close cooperation between people and robots are not a song of the distant future, but a real challenge "the factories of tomorrow ”. Manufacturing companies that position themselves to be just that, invest in theirs branding and use the tools that are expected of them target group.

There is also a growing interest in non-standard production. Customers want tailor-made solutions, taking into account their specific preferences. In addition, modern communication and monitoring systems allow you to track the product life cycle from its design and production to disposal, thanks to which it is possible to analyze customer needs on an ongoing basis, as well as efficiently manage maintenance services.