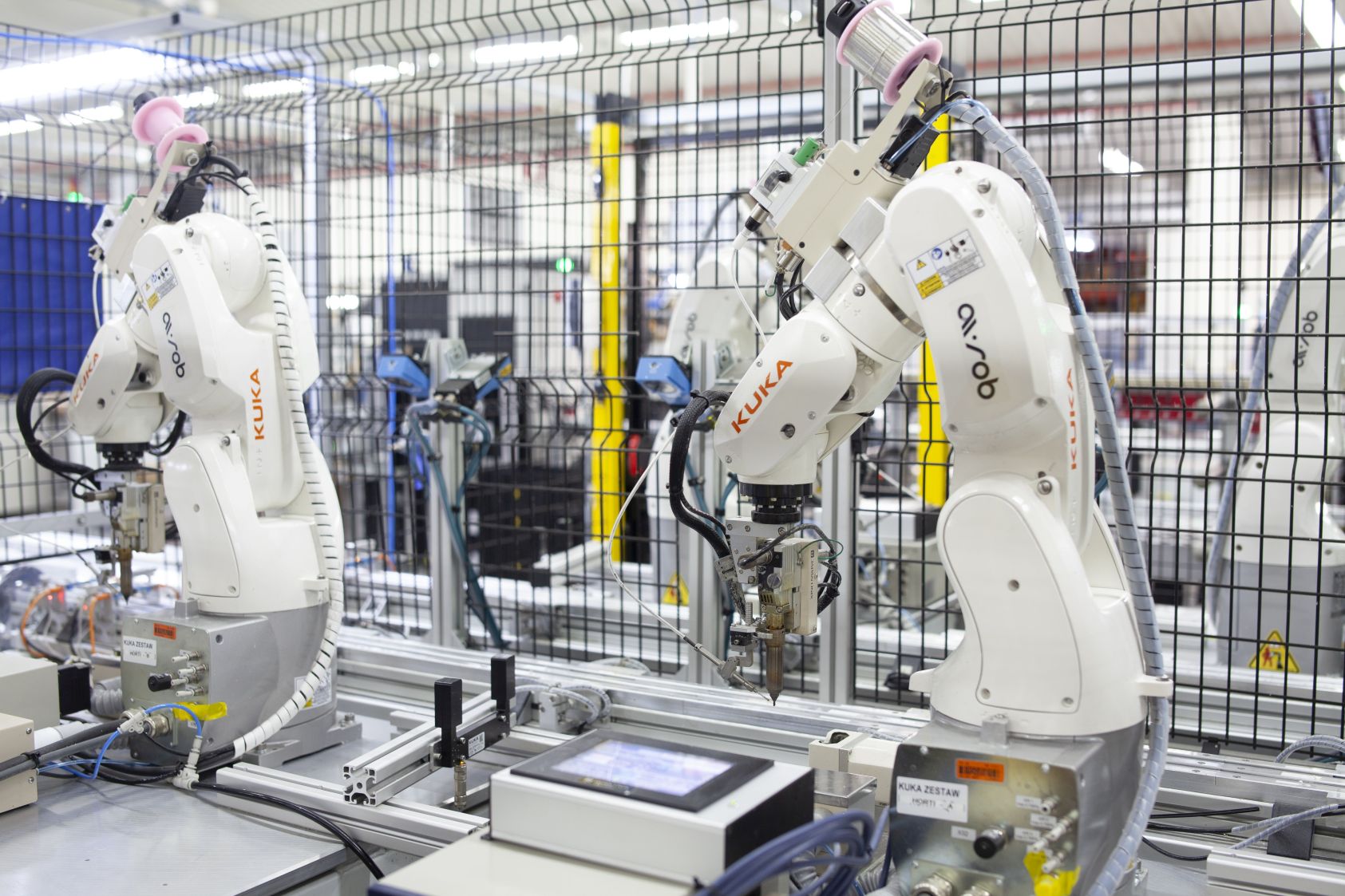

Automation and robotization are key trends in the high-tech industry. Opinions on this subject are clear among FITECH experts: companies that automate their processes at the earliest stage of development have a chance to gain a strategic advantage over the competition.

Industrial robots are replacing the work of human hands more and more quickly. According to the data of the International Federation of Robotics, in 2021 per 10,000 There were 126 robots employed in factories - almost twice as many as in 2015. Poland's result is more modest than the world average. The density of robotization in the domestic industry is 52 robots per 10,000. employees, which is much less than in the neighboring Slovakia (175) or the Czech Republic (162). Nevertheless, the level of use of robots in the Polish industry is consistently growing. For example, in 2015-2020, in the electrical and electronics industries, the average annual growth rate of robotic unit installations was 37%.

- Polish industry still has a lot of catching up to do in the field of robotization, which translates into great growth potential in this market - says Łukasz Samson, operations director at FITECH. Expert opinions show that Polish companies can significantly increase their productivity thanks to robotization and automation. Łukasz Samson emphasizes that this type of investment may seem expensive at first, but abandonment is much more costly. The lack of modernization condemns the company to high running costs related to the need to pay for manual work and a weakening position in relation to the competition, which implements the latest technologies.

FITECH: opinions on the benefits of automation and robotization

Not only companies that provide robotic solutions, such as FITECH, have a positive opinion about automation and robotization - these opinions are also shared by customers. Enterprises that have implemented the latest high-tech solutions in their plants have largely freed themselves from the shortcomings of manual work. The most important "disadvantages" are the costs of recruiting and training new employees. The question of quality is also important. Robots are in many respects more precise and provide higher quality in assembly or other production activities. In many cases, they are also able to run faster than manual workers. The issue of infrastructure is also important. The premises where people work must be properly adapted in terms of safety and ergonomics - and this comes with additional costs.

An additional benefit of automation is the ability to engage employees in more creative tasks. Activities "taken over" by robots are often simple and monotonous, and therefore burdensome for humans in the long run. A separate issue is the possibility of combining robotization with data analysis. The operation of machines equipped with advanced software can be monitored in a number of ways. The data obtained in this way is a source of valuable information that enables the optimization of both industrial and business processes. This allows for additional - often very significant - benefits from the implementation of innovations.

FITECH provides advanced solutions

FITECH has been gathering opinions and experience for years. This high-tech company from Małopolska has been operating on the market for over two decades. The company deals with the broadly understood automation of industrial processes, such as assembly, soldering, twisting, testing, marking and packaging. FITECH provides comprehensive solutions, including the implementation of robotic stations and IT systems for managing robots or analyzing data obtained during the processes. The company has extensive experience, including in the field of electronics testing. Among its areas of specialization, FITECH mentions, among others, PCBA functional tests, EOL tests, security tests and optical inspection. The recipients of the services of the Małopolska company are Polish and foreign companies from the electronics, automotive, lighting and medical industries.

Some FITECH solutions are based on artificial intelligence (AI) algorithms. They are used, inter alia, in the process of assembling electronics, in intelligent optical control or intelligent LED tests.

The use of AI systems in image analysis allows you to improve the quality of the final product, obtain higher work efficiency, significantly accelerate processes and automatically adapt tools to changing product parameters. Artificial intelligence solves, among others the problem of false alarms during automatic vision inspection and allows you to avoid the costs associated with the need to reprogram machines with changing production. In addition, the data obtained during intelligent image analysis allows the identification of negative trends in the production process that may generate losses.

FITECH also has a well-developed software outsourcing department. The company carries out advanced IT projects commissioned by clients from different parts of the world. These are primarily production-related projects that fit into the area of industry 4.0, the Internet of Things or autonomous transport.

FITECH - opinions based on many years of market experience

With such extensive experience, the experts of the Małopolska company have a great understanding of the situation on the automation and robotization market. In the opinion of FITECH specialists, long-term trends in both areas are definitely growing. Investments should not be delayed any more - the sooner modern solutions are implemented, the greater the savings and benefits for the client will be.

What are the benefits of automating the soldering process?

Fitech provides advanced soldering automation solutions that increase production efficiency and throughput. In order to stand out from the competition, the entrepreneur should place a strong emphasis on the accuracy, speed and consistency of the process.

Meeting the above requirements influences positive customer feedback. Soldering robots that work 24/7 can help, which translates into production efficiency. These devices work quickly and accurately, so they meet the needs of even the most demanding customers.

Electronic components are getting smaller and the demand for lighter, more efficient and faster devices will only increase. PCBs are filled with components and the choice of soldering method affects their appearance. Opinions about the product will translate into customer satisfaction. Therefore, when designing a tile, you should pay attention not only to the placement of individual elements, but also to making strong, durable connections between them.

Fitech - opinions on why it is worth robotizing soldering

If we decide to solder by hand, we have to take into account that any errors will be difficult to detect. To avoid this, it is a good idea to automate the entire process. A professional can program the robots to a specific path and quality level. Thanks to this, the devices accurately solder each joint. If there are any errors, they can be easily eliminated. It is enough to reprogram the robot to reduce production costs - we make sure that such solutions are available to everyone. This is how we operate at Fitech - opinions about more efficient work, thanks to the implementation of our projects, are an incentive for further development,

The remarkable versatility of the robots is also noteworthy. Regardless of whether you want to solder battery cables or individual pins with them, they will certainly make the task easier. Robots largely mirror the work of traditional machines, while improving the quality of production and increasing its stability. No wonder then that more and more factories are automating the soldering process.

Automated THT assembly: advantages

The assembly of THT elements is tedious and monotonous, at the same time it requires high precision and dexterity. This increases the risk of errors, which increases production costs and reduces quality. It is therefore worth paying attention to automated solutions based on advanced algorithms.

The EMS industry is struggling with various difficulties, including shortages of staff, rapidly rising employment costs and a high risk of making mistakes when manually assembling THT. When deciding to automate the process, the entrepreneur has to face other challenges. The experts from Fitech know this. Opinions that more and more tasks can be entrusted to robots are not exaggerated.

First of all, pay attention to the dimensions and shape of components such as connectors, varistors or chokes. In addition, the station should be automated in terms of the type of packaging and the spacing of leads. Reading the opinions on the service proposed by Fitech, it can be noticed that the provided solution allows for the formation and assembly of components with various variables.

It is worth emphasizing that the automation of the workplace does not reduce the effectiveness of the process. The proposed solution ensures repeatability, and additionally minimizes the risk of deformation or damage. The ease and speed of programming the machine is also noteworthy. Depending on the needs, robots can completely or partially replace manual assembly.