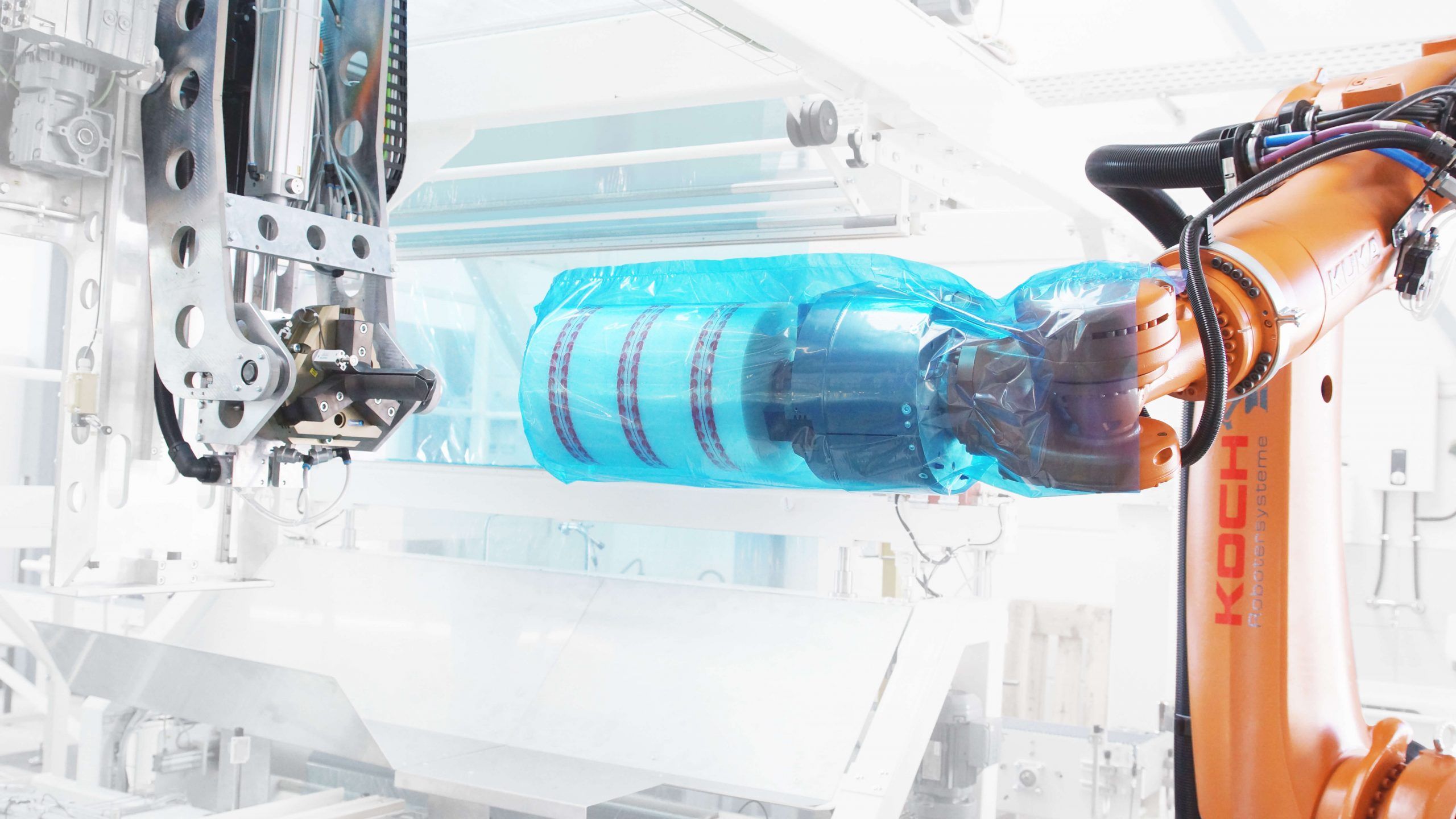

The numbers do not lie - the robotization density index in Poland is growing every year. This means that in the near future, the view of a warehouse or production hall where many people work will be less and less common. It is worth not only going with the times, but also investing in robotization as early as possible. One of the companies that can help with this is KOCH Robotersysteme. Opinions about the robotic systems it creates, used in palletizing, definitely encourage people to become interested in its offer.

Robotization and the company's image

As a PR agency, we approach the issue related to robotization primarily from the marketing side. Let us remind you that the purpose of all activities in the field of Public Relations is to shape the desired image of the company in the environment. Therefore, if a company wants to be perceived as modern, professional, developmental and well-organized, it should include in its strategy investing in advanced machinery and try to make these investments visible in its advertising materials. This is important especially from the point of view of companies where product quality is of great importance.

This approach is shared by many KOCH Robotersysteme customers. The opinions expressed by them often show that although the company's technical base is seemingly invisible and meaningless for the end customer, it has a huge potential to shape the perception of the company. This does not mean that you have to decide on full robotization or automation right away. You can start with minor changes, e.g. robotization of the palletizing process itself.

KOCH Robotersysteme - opinions and facts about robotic palletization

Palletization is one of the most common activities performed in warehouses or production halls. It consists in placing goods on pallets in a specific way in order to facilitate their shipment or storage. Due to the fact that it is a repetitive activity, properly programmed robots, i.e. palletizers. This is also confirmed by the customers of KOCH Robotersysteme. The opinions they express about the robotic systems implemented by this company even say that in many respects they perform better than humans.

Advantages of robotic palletization

There are many reasons for investing in an automatic palletizing solution. The most important, of course, are those related to saving - both money and time. By implementing palletizing robots in our facility, we can resign from employing an employee who has been involved in this tedious activity so far. Thanks to this, we not only reduce costs, but also gain. A palletiser, unlike a human, is able to work 24 hours a day. In turn, due to the fact that the number of loads transferred in the same unit of time increases, orders can be processed even faster. Reliability is another feature of the palletizing robots - including those from KOCH Robotersysteme. Opinions about their work often relate to faultlessness.

No mistakes in robotic palletization is another argument to put it above manual palletization. Remember that faultlessness means not only placing the goods on a pallet in accordance with the pattern, but also a significant reduction in the situations in which the load is accidentally dropped during transport. If we palletize delicate and fragile items, it translates into a significant reduction of losses.

Contrary to appearances, automatic palletization is not a solution reserved only for large enterprises. It can also work well in smaller ones with a relatively large and stable production volume or in those where manual palletization is extremely onerous for the employee. We are talking about working with heavy loads or in uncomfortable conditions, for example due to low temperature or noise. Increasing the safety of employees is therefore another advantage of robotic palletization.

KOCH Robotersysteme - opinions about the systems of this brand

Functionality is something that characterizes the system solutions provided by KOCH Robotersysteme. User feedback is a tribute to the constructors, first of all, for the fact that the robots can handle the palletization of really diverse products. Shape, dimensions and weight are not a major problem. All you need to do is match the appropriate gripper and software. For example, KOCH EasyPallet is a software for products with round, oval or rectangular shape as well as for goods packed in sacks or bags. In turn, when it comes to grippers, we can choose from, among others internal, vacuum and fork and clamp type grippers. The most advanced robotic models are able to grasp even entire layers of products.

However, the possibilities of the palletizers mentioned do not end there. In addition to the mere transfer of products, they also take care of their proper protection. We are talking about the ability to separate individual layers with protective separators. Moreover, when the pallet is fully loaded, the robot will handle the delivery of the next empty pallet itself. It is equally good at depalletizing, i.e. transferring loads from a pallet to conveyor belts. There is also much talk about the flexibility of KOCH Robotersysteme system solutions. Opinions indicate that many entrepreneurs appreciate the fact that they can reprogram the robot at any time, i.e. change the palletization pattern.

Automated palletization is certainly a good step towards savings, improvements and building a positive image of the company. KOCH Robotersysteme has been implementing robotic systems for over 25 years and offers solutions tailored to the needs of a specific customer. This is a partner worth considering working with.